- Overview

- Product Description

Basic Info.

Model NO.

dk-cb004

Product Name

Inert Alumina Balls

Sample

Available

Color

White

Al2O3+Sio2

>92%

Fe2o3

<1%

Size

as Per Customer′s Request

Service Temperature

1600c

Application

Covering or Supporting Media of The Catalyst

OEM

Acceptable

Drop Test

100% Survived

Transport Package

Woven Bag or Ton Bag

Specification

As per your request

Trademark

DKJL

Origin

China

HS Code

69141000

Production Capacity

3000 Ton/Tons Per Month

Product Description

Hot Sale High Precision zirconia Ceramic Grinding Ball

Pictures of inert alumina ceramic balls

Inert ceramic balls's Characteristics and advantages

1. High mechanical strength (Monolithic spheres will not split, crack or spall in use)

2. High temperature resistance

3. Lower water absorption

4. Quite excellent chemical stability

5. Can resist corrosion of acid, alkali and other organic solvent

6. Excellent thermal shock resistance (can withstand the temperature urgent changes occurred in production process)

7. Trouble-free reactor filling due to high crush strength

8. Will not plug catalyst bed, optimizing the process efficiency by keeping the pressure drop low and catalyst activity high

9. No contaminate catalyst due to maximize resistance to attrition, extending the catalyst Activity life and reduce the operation cost

Application:

Inert alumina ceramic balls are widely used as the covering or supporting media of the catalyst in the reactors and tower packing in many fields such as petroleum, chemical industry, chemical fertilizer and environmental protection etc. The main role is to buffer the impact of liquid and gas to the catalyst in the reactor, protect the catalyst and improve the distribution of liquid and gas in the reactor.

Inert alumina ceramic ball's Technical Index

Different common sizes are available, uncommon sizes can be customized as your request.

Dimensions, tolerances, bulk density, specific surface area, void volume and compressive strength

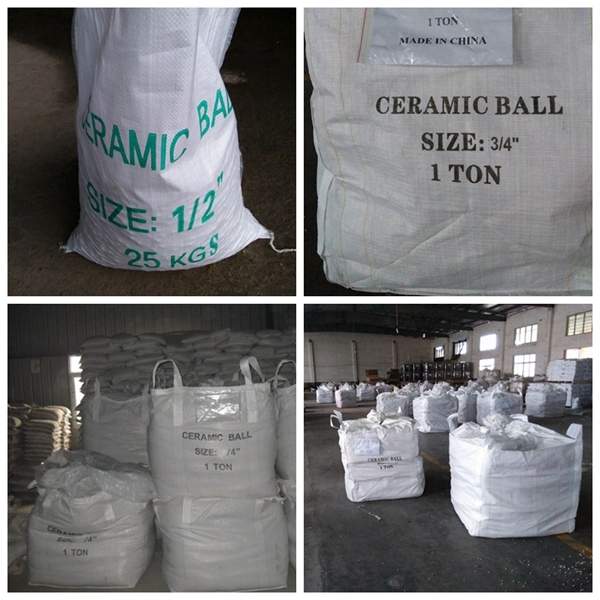

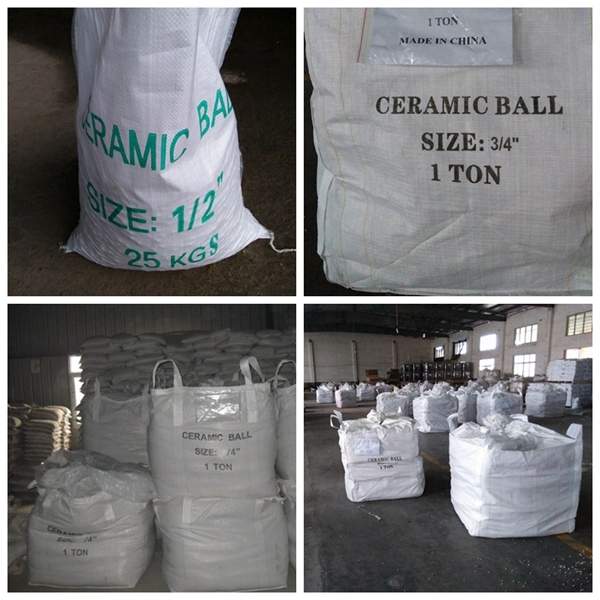

Package: Ton bag or Woven bag.

We also received OEM service; the package can be designed according to your requirements.

Shipping: By vessel or by train from any Chinese port, Samples can be delivered by International express.

Package pictures of inert alumina ceramic balls

Our Service:

1. Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand, quickly respond mails and provide solutions.

2. Sample evaluation

Sample and trial order is accepted for the quality evaluation.

3. Strict quality control

Arrange production on time and control quality strictly.

4. Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5. Professional Services

Provide all the detailed news and pictures from order to delivery;

Offer relative export documents and original certificate if needed;

Warm and considerable after-sale service

FAQ:

1. How can I get your prompt quotation?

We can give you reply with quotation quickly if you kindly send the inquiry with following factors: content of AL2O3, ball diameter, application and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don't conform to customer's samples or have quality problems, our company will be responsible to make compensation for it based on enough evidences.

7. What is the HS code?

The HS code is 69141000

Welcome your inquiry and expect to provide satisfactory products and services for you.

Inert alumina ceramic balls are manufactured from very high quality chemical-porcelain clay materials. According to the different content of Al2O3, the packing ceramic ball is divided into: common ceramic ball, inert ceramic ball, medium alumina ball, high alumina ball and 99% alumina Ball, actived alumina ceramic ball, opening hole ceramic ball, micro porous ceramic ball, heat storage ceramic ball.

Pictures of inert alumina ceramic balls

Inert ceramic balls's Characteristics and advantages

1. High mechanical strength (Monolithic spheres will not split, crack or spall in use)

2. High temperature resistance

3. Lower water absorption

4. Quite excellent chemical stability

5. Can resist corrosion of acid, alkali and other organic solvent

6. Excellent thermal shock resistance (can withstand the temperature urgent changes occurred in production process)

7. Trouble-free reactor filling due to high crush strength

8. Will not plug catalyst bed, optimizing the process efficiency by keeping the pressure drop low and catalyst activity high

9. No contaminate catalyst due to maximize resistance to attrition, extending the catalyst Activity life and reduce the operation cost

Application:

Inert alumina ceramic balls are widely used as the covering or supporting media of the catalyst in the reactors and tower packing in many fields such as petroleum, chemical industry, chemical fertilizer and environmental protection etc. The main role is to buffer the impact of liquid and gas to the catalyst in the reactor, protect the catalyst and improve the distribution of liquid and gas in the reactor.

Inert alumina ceramic ball's Technical Index

| Specification | Common Ceramic Ball | Inert Ceramic Ball | Medium Alumina Ball | High Alumina Ball | 99% Alumina Ball |

| Al2O3 + SiO2 (%) | >93 | >92 | >93 | >94 | >99 |

| Al2O3 (%) | 17-23 | 23-30 | 47-56 | 90-93 | 99 |

| Fe2O3 (%) | <1 | <1 | <1 | <1 | <1 |

| CaO (%) | <0.5 | <1.5 | <2 | <4 | 0.2 |

| MgO (%) | <0.5 | <2.5 | <0.5 | <0.5 | 0.1 |

| K2O + Na2O (%) | <4 | <4 | <3.5 | <4 | >0.5 |

| TiO2 | <0.5 | <0.1 | <0.1 | 0.5 | |

| Leachable Iron (%) | <0.1 | <0.001 | <0.001 | ||

| Water Absorption (%) | <0.5 | <0.2 | <2 | <3 | 2.0-6.0 |

| Bulk Density (g/cm3) | 1.35-1.40 | 1.35-1.40 | 1.35-1.45 | 1.8-2.0 | 1.8-2.0 |

| Operation Temp. max. | >1100 | >1100 | 1480 | 1760 | |

| Mohs Hardness (scale) | >6.5 | >7 | >7 | >7 | >7.5 |

| Crush Strength | KN/particle | ||||

| 1/4 inch (6mm) | >0.5 | >0.54 | >0.56 | >0.44 | >1 |

| 1/2 inch (13mm) | >1.5 | >1.67 | >1.56 | >1.99 | >3 |

| 3/4 inch (19mm) | >4.15 | >4.21 | >2.89 | >3.21 | >5 |

| 1 inch (25mm) | >6.07 | >6.22 | >4.89 | >5.33 | >8 |

| 1-1/2 inch (38mm) | >8.52 | >8.92 | >5.33 | >5.28 | >8 |

| 2 inch (50mm) | >9.7 | >9.8 | >6.22 | >8 | >15 |

Different common sizes are available, uncommon sizes can be customized as your request.

Dimensions, tolerances, bulk density, specific surface area, void volume and compressive strength

| Dimensions (mm)- tolerances | bulk density (kg/m³) | specific surface area (m²/m³) | · Void volume (%) | compressive strength (kg) |

| 1/8"-3mm 2.5-3.5mm | 1310 | 720 | 44 | 30 |

| 1/4"-6mm 5.5-6.5mm | 1310 | 520 | 44 | 50 |

| 3/8"-9mm 8-10mm | 1310 | 360 | 44 | 120 |

| 1/2"-13mm 12-14mm | 1290 | 275 | 45 | 180 |

| 3/4"-19mm 18-20mm | 1290 | 190 | 45 | 300 |

| 1"-25mm 24-26mm | 1250 | 144 | 45 | 400 |

| 1¼"-32mm 31-33mm | 1250 | 120 | 45 | 520 |

| 1½"-38mm 37-39mm | 1250 | 100 | 45 | 600 |

| 2"-50mm 48-53mm | 1250 | 75 | 45 | 720 |

Package: Ton bag or Woven bag.

We also received OEM service; the package can be designed according to your requirements.

Shipping: By vessel or by train from any Chinese port, Samples can be delivered by International express.

Package pictures of inert alumina ceramic balls

Our Service:

1. Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand, quickly respond mails and provide solutions.

2. Sample evaluation

Sample and trial order is accepted for the quality evaluation.

3. Strict quality control

Arrange production on time and control quality strictly.

4. Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5. Professional Services

Provide all the detailed news and pictures from order to delivery;

Offer relative export documents and original certificate if needed;

Warm and considerable after-sale service

Company Information

DKJL refractories exporting company is one of the most professional suppliers of refractories in China. Our main products are refractory and thermal insulation materials, heating elements, industrial ceramics. They are available in various sizes and shapes. Our products enjoy a good reputation for their excellent quality and service in domestic and international markets.

|  |

|  |

FAQ:

1. How can I get your prompt quotation?

We can give you reply with quotation quickly if you kindly send the inquiry with following factors: content of AL2O3, ball diameter, application and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don't conform to customer's samples or have quality problems, our company will be responsible to make compensation for it based on enough evidences.

7. What is the HS code?

The HS code is 69141000

Welcome your inquiry and expect to provide satisfactory products and services for you.