- Overview

- Product Parameters

- Product Description

- Company Profile

- Why Choose Us

- FAQ

Basic Info.

Product Description

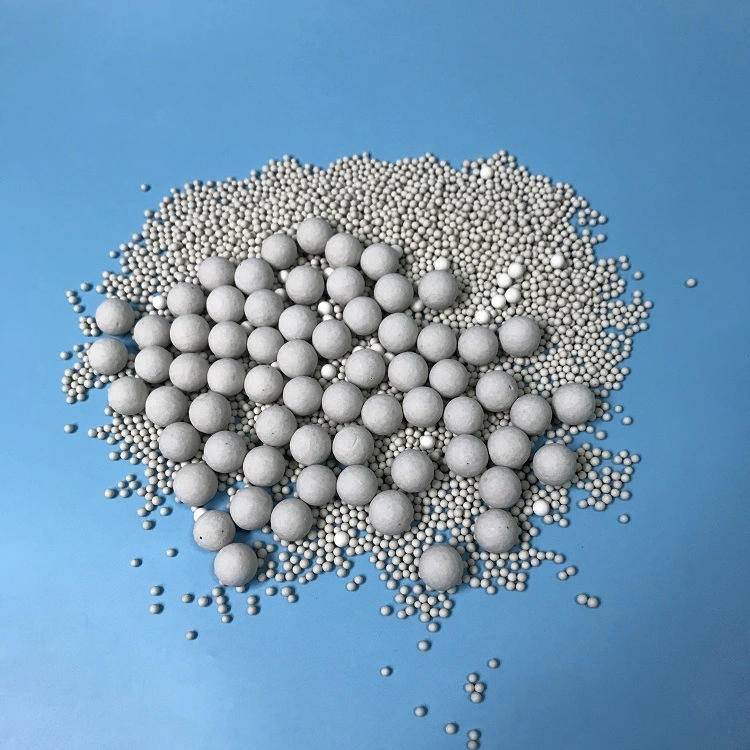

Customized industrial precision zirconia Alumina Supporting Media ceramic Grinding balls

| Type | Item | Normal ceramics | Low alumina | Mid alumina | High alumina | Corundum |

| Chemical composition% | Al2O3 | 20-30 | 31-45 | 46-70 | 71-90 | >90 |

| Al2O3+SiO2 | ≥90 | |||||

| Fe2O3 | ≤1 | |||||

| Water absorption,% | ≤5 | ≤8 | ||||

| Acid resistance,% | ≥90 | |||||

| Alkali resistance,% | ≥85 | |||||

| Thermal shock resistance,°C | ≥300 | |||||

| Thermal resistance,°C | ≥1000 | ≥1200 | ≥1300 | ≥1400 | ≥1500 | |

| Crushing strength Kn/piece | 3mm | ≥0.2 | ≥0.25 | ≥0.3 | ≥0.35 | ≥0.4 |

| 6mm | ≥0.5 | ≥0.6 | ≥0.65 | ≥0.7 | ≥0.8 | |

| 8mm | ≥0.7 | ≥0.8 | ≥0.9 | ≥1 | ≥1.2 | |

| 10mm | ≥0.85 | ≥1 | ≥1.2 | ≥1.5 | ≥1.9 | |

| 13mm | ≥1.8 | ≥2.3 | ≥3 | ≥4 | ≥5.8 | |

| 16mm | ≥2.3 | ≥3 | ≥4.5 | ≥6 | ≥7 | |

| 20mm | ≥4.3 | ≥5 | ≥6 | ≥7.5 | ≥9 | |

| 25mm | ≥6.2 | ≥7 | ≥8 | ≥10 | ≥12 | |

| 30mm | ≥7 | ≥8 | ≥10 | ≥12 | ≥14 | |

| 38mm | ≥8.8 | ≥10 | ≥12 | ≥16 | ≥18 | |

| 50mm | ≥12 | ≥13 | ≥15 | ≥18 | ≥21.5 | |

| 76mm | ≥16 | ≥18 | ≥20 | ≥22 | ≥25 | |

| Bulk density,kg/m3 | 1300-1400 | 1400-1500 | 1500-1600 | 1600-1800 | ≥1800 | |

| The data of bulk density is given for reference only,not as aacceptance criterion | ||||||

Typical Application:

a) high temperature and steam

b) has very excellent thermal properties, with its high density high-temperature resistance 1550

c) it's suitable for applications in olefin processes, such as ethylene dryers

Size tolerance:

Diameter | 3 | 6 | 8 | 10 | 13 | 16 | 20 | 25 | 30 | 38 | 50 | 75 |

Size tolerance | ±1.0 | ±1.5 | ±2.0 | ±3.0 | ||||||||

It's widely used in petroleum, chemical, fertilizer, gas and environmental protection industries, as a catalyst in the reactor to cover support material and tower packing.It has a high temperature and high pressure resistance, bibulous rate is low, the characteristics of the chemical performance is stable.Can withstand the erosion of acid, alkali and other organic solvents, and can endure in the production process of temperature changes.Its main function is to increase gas or liquid distribution points, support and protection intensity is not high activity of the catalyst.

PINGXIANG A & R CERAMICS CO., LTD. has remained unwavering in its commitment to quality, uncompromising in its attention to detail and focused on being at the forefront of technology of making Honeycomb ceramic, Catalyst support ball, Random Packing, Structured packing, Activated Alumina, Molecular Sieve.

Ever keeping an eye on long run, A& R connected a gas pipeline with Pingxiang Iron& Steel company in 2000, not only did it protect the environment from pollution, it also cleared the products from impurities and blemishes. At the same time, A & R introduced a deferrization equipment to lower the iron contains less than 0.6'

1.15 years of professional production industrial ceramics factory

2. High quality products with low price

3. High precision parts with lowest tolerance

4. Show time for production

5. Has a group of experienced, professional and efficient R&D team

6. Has a good reputation in China and abroad.

7. MOQ is not limited, small quantity is welcome.

8. Vigorous team and good after-sales service

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance, balance before shippment.