Basic Info.

Universal

Yes

Type

Bearing Ball

Material

Carbon Steel

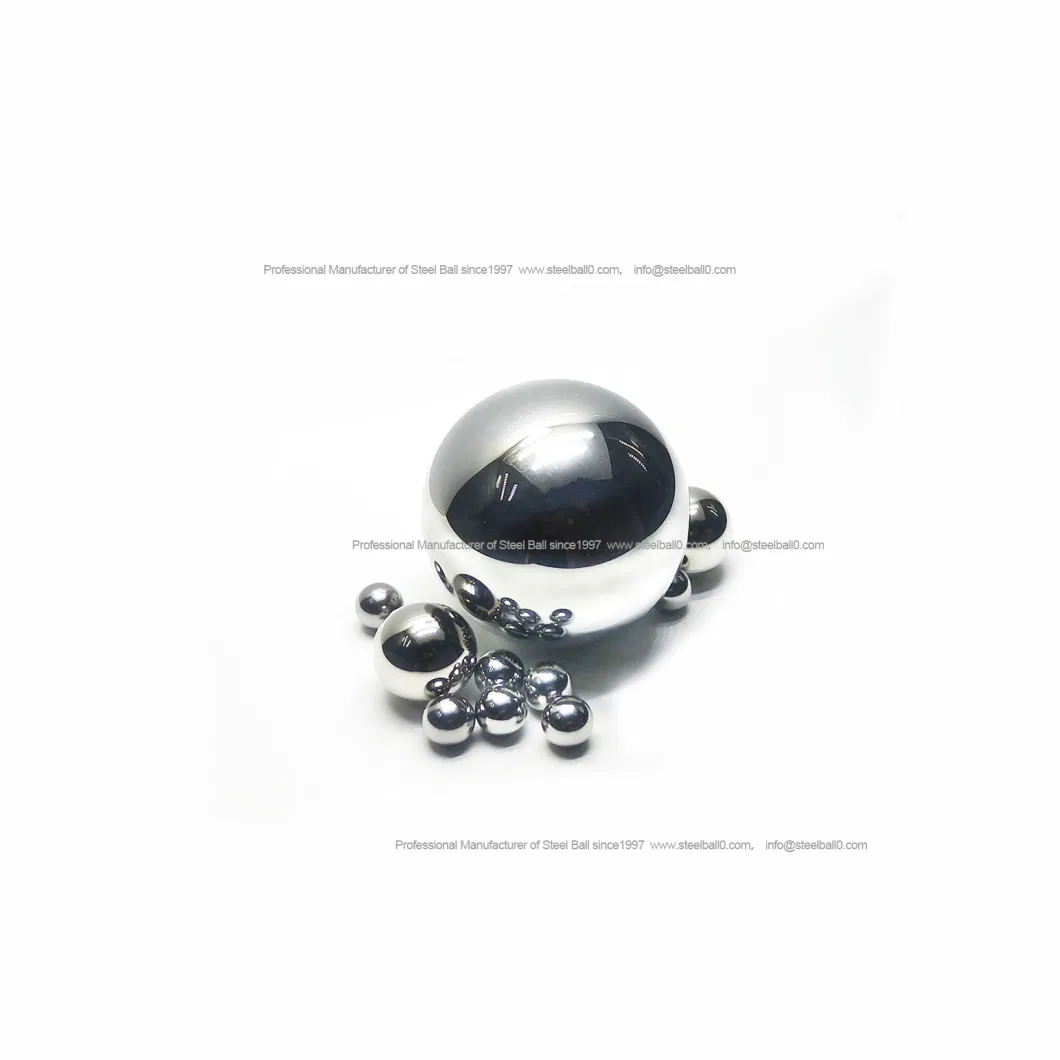

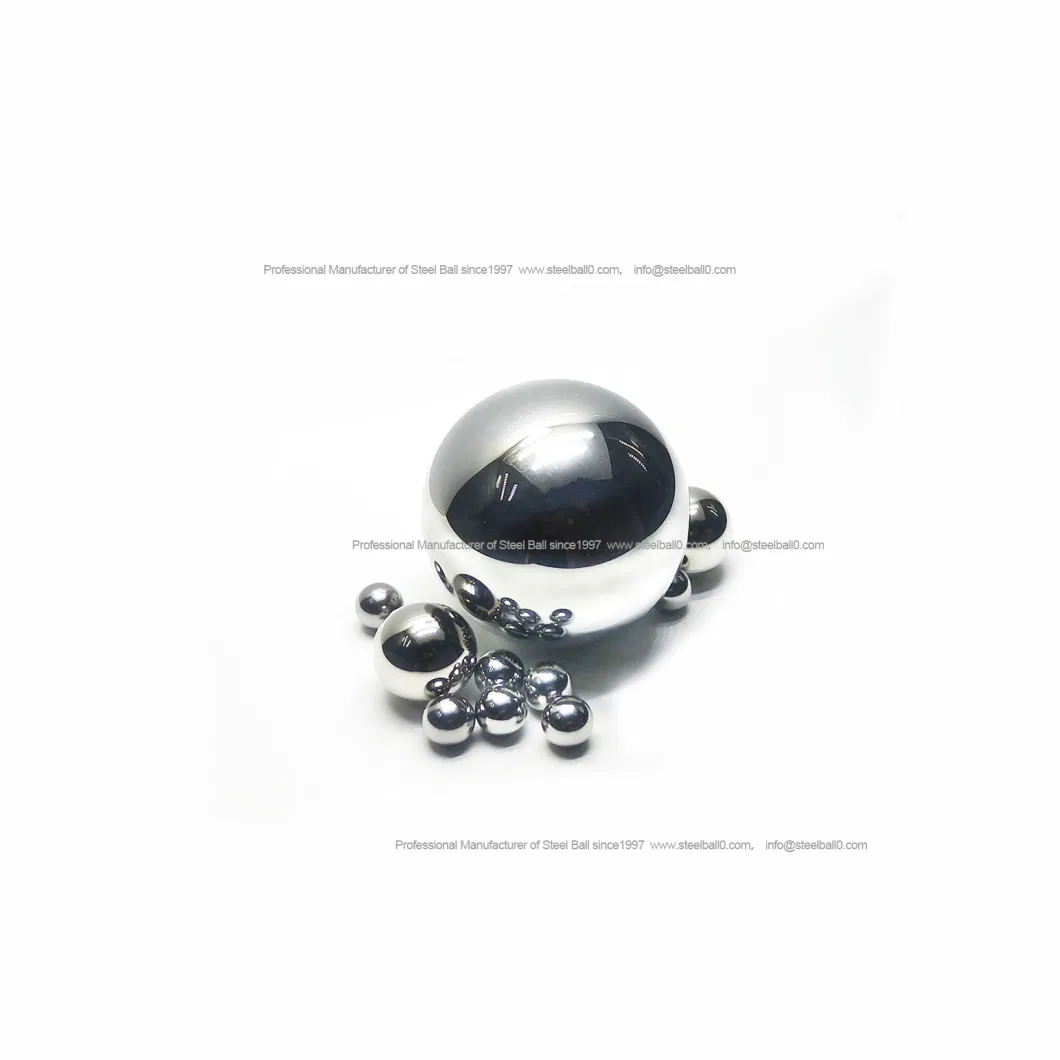

Product Name

6mm Carbon Steel Ball

Transport Package

Carton

Specification

0.5-76.2mm

Origin

China

Production Capacity

300 Tons Per Month

Product Description

China factory wholesale G1000 Hrc 58-62 6mm carbon steel ball for bicycle

Pls fell free to contact me if you interest to our steel ball

Contact:linda

BREIF INTRODUCTION

Carbon steel balls are available at soft steel ballsand hard steel balls, which carburized and case-hardened and through-hardenedsteel balls. Carbon steel ballsare offered in low carbon steel and high carbon steel. Carbon steel ballsare widely used in automotive applications, for semi-precision bearings, such as bicycle and motorcycle balls and in transmission applications such as casters, locks, drawer slides ,roller skates, slides, trolleys and conveyors..

APPLICATION

Heavy duty and high-speed bearing,linear motion guidance system(ex.ball screw),metal milling,ink and paint grinding,chemical industry,food industry,power plant.

PRODUCTION PROCESS

Raw Material,wire drawing:the wire rod is drawn to the required size,in closer tolerances so that it can be used in cold forging.

Cold forgig:Calculated length of wire is sheared and cold forged in a close die to give it the spherical shape.

Flashing: The rolling between plates with concentric grooves in order to eliminate the heading witness marks and to increase the precision of the ball, In this operation the spheres are ground between two concentric pressure plates to correct the sherical shape and remove the seam formed in the cold forging.

Heat treating: Carbon steel balls are next carburized and hardened. Heat treatment imparts the desired hardness and case depth.

Descaling: This step removes the residues and by-products for the preceding process.

Hard Grinding: Here the hardened balls are ground to improve suface finish and geometrical parameters. Several careful grinding processes with ceramic wheels lead to a higher size precision preparing the balls for the next final lapping operation.

Finishing:Proprietary chemical and mechanical processes give the balls their final micro-smoothed finish, increasing wear resistance and product longevity.

Inspecting: All products pass through at least two 100% inspection stages, using proprietary,automated inspection processes.

COMPANY INFORMATION

At hengda(HD) steel balls manufacturing research, develop and continually test our steel balls to be confident we not only deliver the high quality steel balls, but the most effevtive service as well.

Engaged in steel balls area since1997, HD steel balls manufacturing focus on carbon steel balls, stainless steel balls, high chrome steel balls,bearing steel balls .The diameter from 1.0mm to 76.2mm. Their grade of accuracy is G10-G1000. High precision steel balls are mainly used for ball bearing, while semi-precision steel balls (grade100 to 1000) are applied to bicycle/motor cycle parts caster wheels,hardware, draw side, toys, game ball ,wheels, instruments, rail,pumps,polishing, Cosmetics ,the solid smash and so forth.

ADVANTAGES

Pls fell free to contact me if you interest to our steel ball

Contact:linda

BREIF INTRODUCTION

| Material | Carbon steel |

| Size | 0.5mm-76.2mm |

| Grade | G10-G1000 |

| Category | Soft ball/Hard ball |

| Feature | low cost,widely application,abrasion resistance |

| Application | Bicycle parts/pulley/joint/toy/tool |

| Model Number | AISI1008-1086 |

| Port | Qingdao/Ningbo/Shanghai |

Carbon steel balls are available at soft steel ballsand hard steel balls, which carburized and case-hardened and through-hardenedsteel balls. Carbon steel ballsare offered in low carbon steel and high carbon steel. Carbon steel ballsare widely used in automotive applications, for semi-precision bearings, such as bicycle and motorcycle balls and in transmission applications such as casters, locks, drawer slides ,roller skates, slides, trolleys and conveyors..

| AISI Number | C% | Si% | Mn% | Mo% | P% | S% | Hardness |

| AISI 1010 | 0.08~0.13 | 0.30Max | 0.50Max | 0.07Max | 0.06Max | Case Hardened | |

| AISI 1015 | 0.13~0.18 | 0.10~0.30 | 0.30~0.60 | 0.04Max | Case Hardened | ||

| AISI 1045 | 0.43~0.50 | 0.10~0.30 | 0.60~0.90 | 0.04Max | 0.05Max | Through Hardened | |

| AISI 1085 | 0.83~0.88 | 0.10~0.30 | 0.30~0.70 | 0.04Max | 0.04Max | Through Hardened |

APPLICATION

Heavy duty and high-speed bearing,linear motion guidance system(ex.ball screw),metal milling,ink and paint grinding,chemical industry,food industry,power plant.

PRODUCTION PROCESS

Raw Material,wire drawing:the wire rod is drawn to the required size,in closer tolerances so that it can be used in cold forging.

Cold forgig:Calculated length of wire is sheared and cold forged in a close die to give it the spherical shape.

Flashing: The rolling between plates with concentric grooves in order to eliminate the heading witness marks and to increase the precision of the ball, In this operation the spheres are ground between two concentric pressure plates to correct the sherical shape and remove the seam formed in the cold forging.

Heat treating: Carbon steel balls are next carburized and hardened. Heat treatment imparts the desired hardness and case depth.

Descaling: This step removes the residues and by-products for the preceding process.

Hard Grinding: Here the hardened balls are ground to improve suface finish and geometrical parameters. Several careful grinding processes with ceramic wheels lead to a higher size precision preparing the balls for the next final lapping operation.

Finishing:Proprietary chemical and mechanical processes give the balls their final micro-smoothed finish, increasing wear resistance and product longevity.

Inspecting: All products pass through at least two 100% inspection stages, using proprietary,automated inspection processes.

COMPANY INFORMATION

At hengda(HD) steel balls manufacturing research, develop and continually test our steel balls to be confident we not only deliver the high quality steel balls, but the most effevtive service as well.

Engaged in steel balls area since1997, HD steel balls manufacturing focus on carbon steel balls, stainless steel balls, high chrome steel balls,bearing steel balls .The diameter from 1.0mm to 76.2mm. Their grade of accuracy is G10-G1000. High precision steel balls are mainly used for ball bearing, while semi-precision steel balls (grade100 to 1000) are applied to bicycle/motor cycle parts caster wheels,hardware, draw side, toys, game ball ,wheels, instruments, rail,pumps,polishing, Cosmetics ,the solid smash and so forth.

ADVANTAGES

- Rich Experience:We are professional steel ball producer since 1997.

- Excellent Service:Professional Team dedicated to providing affordable and reliable quality products to all customers with fast response time.

- Most Competitive Price:we have our own factory,so our price will be very competitive.

- Full range: HD steel balls manufacturing focus on carbon steel balls, stainless steel balls, high chrome steel balls,bearing steel balls .The diameter from 0.5mm to 76.2mm. Their grade of accuracy is G10-G1000.