Basic Info.

Model NO.

Carbon Steel Ball

Grade

G20-G1000

Hardness

HRC 58 to 63

Payment

T/T,LC

Delivery Time

20 Days After Receiving The Payment

Package

Box

Transport Package

Plastic Bag+Box+Carton+Wooden Pallet

Specification

0.8-50mm

Trademark

Tangland

Origin

Shandong, China

HS Code

8482910000

Production Capacity

5000 Billion Tons/Month

Product Description

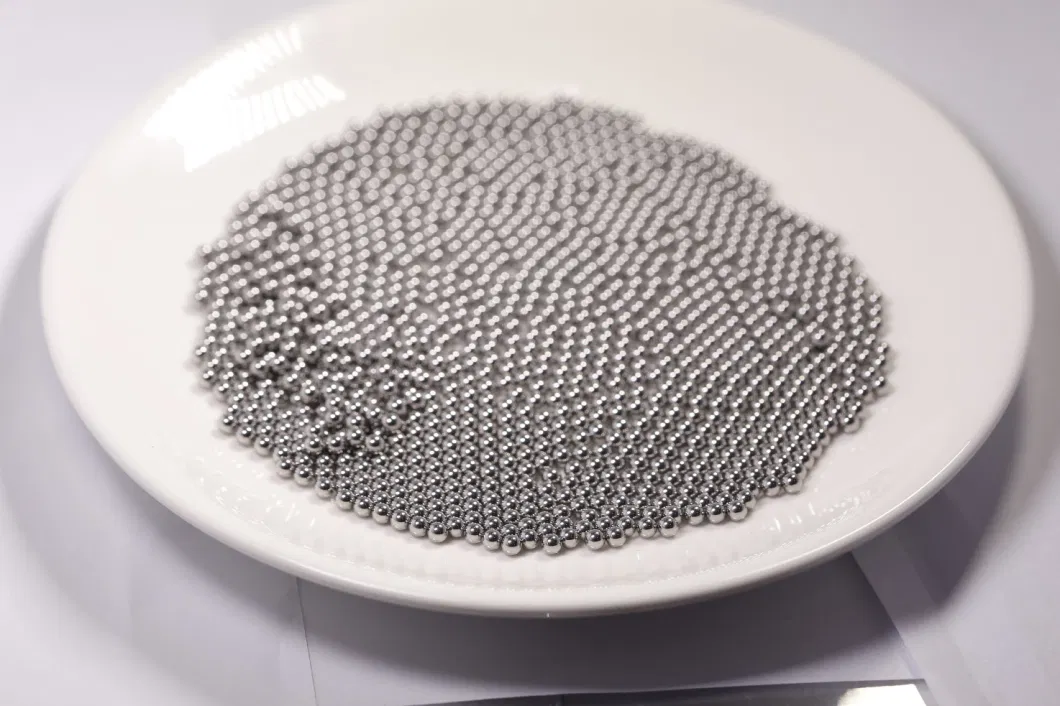

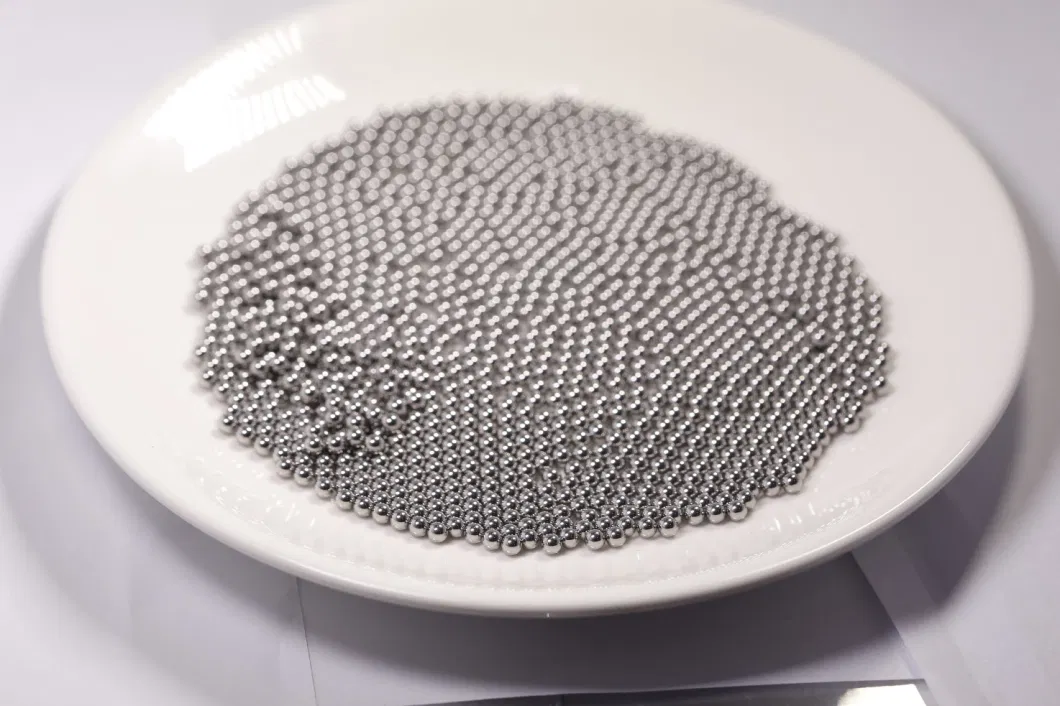

AISI1010 G100-G1000 Lower Price Grinding Carbon Steel Ball/Sphere

Low Carbon steel ball

Grade of ball:20 to 1000

Hardness:HRC 58 to 63

Size:0.8mm-50mm

Application

Bicycle parts, bearings, pulleys, slide rails, handicrafts, shelves,universal balls,bags,anti-friction bearings, steering columns, casters, conveyors and trolleys, roller skates, toys,automotive, locks, drawer slides, welding, capabilities decorative, light-duty, hardware and etc.

High Carbon steel ball

Grade of ball:20 to 1000

Hardness:HRC 60 to 66

Size:2.0mm-25.4mm

Application

Switches for appliances, shotgun cartridge, bicycle parts, auto parts, guide, pulley, joint, toys, tools and so on.

Steel ball grade

Chemical composition

Steel ball grade

Production Process

1.Cold heading process

2.Flashing process

3.Heating treatment process

4.Grinding process

5.Initial grinding process

6.Lapping process

7.Eddy current tested by AVIKO

8.Optical testing

Inspection Machines

Profile roughness tester from England

Germany Zeiss cleanliness analysis system

Taylor roundness instrument from England

S-K-F waviness meter

Germany KB Vivtorinox hardness tester

Finland residual stress analysis

Oxygen nitrogen analyzer from USA

Germany Zeiss metallographic microscope

Steel ball single body vibration measuring instrument

NG Spectrometer spectrometer

Bearing life testing machine

Hydraulic universal testin machine

We produce

Packaging

1. Plastic bag+box+carton+wooden pallet

2. Plastic bag+carton+wooden pallet

3. Export cartons+steel drums+wooden pallets

Low Carbon steel ball

Grade of ball:20 to 1000

Hardness:HRC 58 to 63

Size:0.8mm-50mm

Application

Bicycle parts, bearings, pulleys, slide rails, handicrafts, shelves,universal balls,bags,anti-friction bearings, steering columns, casters, conveyors and trolleys, roller skates, toys,automotive, locks, drawer slides, welding, capabilities decorative, light-duty, hardware and etc.

High Carbon steel ball

Grade of ball:20 to 1000

Hardness:HRC 60 to 66

Size:2.0mm-25.4mm

Application

Switches for appliances, shotgun cartridge, bicycle parts, auto parts, guide, pulley, joint, toys, tools and so on.

Steel ball grade

| μm | ||||||||

| G3 | 0.08 | 0.08 | 0.13 | 0.01 | 0.5 | -5,...,0.5,0,+0.5,...,+5 | 0.1 | -0.2,-0.1,0,+0.1,+0.2 |

| G5 | 0.13 | 0.13 | 0.25 | 0.014 | 1 | -5,...,-1,0,+1,...+5 | 0.2 | -0.4,-0.2,0,+0.2,+0.4 |

| G10 | 0.25 | 0.25 | 0.5 | 0.02 | 1 | -9,...,-1,0,+1,...,+9 | 0.2 | -0.4,-0.2,0,+0.2,+0.4 |

| G16 | 0.4 | 0.4 | 0.8 | 0.025 | 2 | -10,...,-2,0,+2,...,+10 | 0.4 | -0.8,-0.4,0,+0.4,+0.8 |

| G20 | 0.5 | 0.5 | 1 | 0.032 | 2 | -10,...,-2,0,+2,...,+10 | 0.4 | -0.8,-0.4,0,+0.4,+0.8 |

| G24 | 0.6 | 0.6 | 1.2 | 0.04 | 2 | -12,...,-2,0,+2,...,+12 | 0.4 | -0.8,-0.4,0,+0.4,+0.8 |

| G28 | 0.7 | 0.7 | 1.4 | 0.05 | 2 | -12,...,-2,0,+2,...,+12 | 0.4 | -0.8,-0.4,0,+0.4,+0.8 |

| G40 | 1 | 1 | 2 | 0.06 | 4 | -16,...,-4,0,+4,...,+16 | 0.8 | -1.6,-0.8,0,+0.8,+1.6 |

| G60 | 1.5 | 1.5 | 3 | 0.08 | 6 | -18,...,-6,0,+6,...,+18 | 1.2 | -2.4,-1.2,0,+1.2,+2.4 |

| G100 | 2.5 | 2.5 | 5 | 0.1 | 10 | -40,...,-10,0,+10,...,+40 | 2 | -4,-2,0,+2,+4 |

| G200 | 5 | 5 | 10 | 0.15 | 15 | -60,...,-15,0,+15,...,+60 | 3 | -6,-3,0,+3,+6 |

Chemical composition

| Carbon steel ball | Steel Grade | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Ni(%) | Cr(%) | Mo(%) |

| Low carbon steel ball | Q235B | 0.12~0.20 | 0.30max | 0.30~0.70 | 0.045max | 0.045 | ----- | ----- | ---- |

| High carbon steel ball | SWRH82B | 0.79~0.92 | 0.15~0.35 | 0.60~0.90 | 0.025 | 0.025 | ----- | ----- | ---- |

| High carbon steel ball | C86D | 0.083~0.88 | 0.10~0.30 | 0.50~0.80 | 0.035 | 0.035 | ----- | 0.15 | ---- |

Steel ball grade

| G3 | 0.08 | 0.08 | 0.13 | 0.01 | 0.5 | -5,...,0.5,0,+0.5,...,+5 | 0.1 | -0.2,-0.1,0,+0.1,+0.2 |

| G5 | 0.13 | 0.13 | 0.25 | 0.014 | 1 | -5,...,-1,0,+1,...+5 | 0.2 | -0.4,-0.2,0,+0.2,+0.4 |

| G10 | 0.25 | 0.25 | 0.5 | 0.02 | 1 | -9,...,-1,0,+1,...,+9 | 0.2 | -0.4,-0.2,0,+0.2,+0.4 |

| G16 | 0.4 | 0.4 | 0.8 | 0.025 | 2 | -10,...,-2,0,+2,...,+10 | 0.4 | -0.8,-0.4,0,+0.4,+0.8 |

| G20 | 0.5 | 0.5 | 1 | 0.032 | 2 | -10,...,-2,0,+2,...,+10 | 0.4 | -0.8,-0.4,0,+0.4,+0.8 |

| G24 | 0.6 | 0.6 | 1.2 | 0.04 | 2 | -12,...,-2,0,+2,...,+12 | 0.4 | -0.8,-0.4,0,+0.4,+0.8 |

| G28 | 0.7 | 0.7 | 1.4 | 0.05 | 2 | -12,...,-2,0,+2,...,+12 | 0.4 | -0.8,-0.4,0,+0.4,+0.8 |

| G40 | 1 | 1 | 2 | 0.06 | 4 | -16,...,-4,0,+4,...,+16 | 0.8 | -1.6,-0.8,0,+0.8,+1.6 |

| G60 | 1.5 | 1.5 | 3 | 0.08 | 6 | -18,...,-6,0,+6,...,+18 | 1.2 | -2.4,-1.2,0,+1.2,+2.4 |

| G100 | 2.5 | 2.5 | 5 | 0.1 | 10 | -40,...,-10,0,+10,...,+40 | 2 | -4,-2,0,+2,+4 |

| G200 | 5 | 5 | 10 | 0.15 | 15 | -60,...,-15,0,+15,...,+60 | 3 | -6,-3,0,+3,+6 |

Production Process

1.Cold heading process

2.Flashing process

3.Heating treatment process

4.Grinding process

5.Initial grinding process

6.Lapping process

7.Eddy current tested by AVIKO

8.Optical testing

Inspection Machines

Profile roughness tester from England

Germany Zeiss cleanliness analysis system

Taylor roundness instrument from England

S-K-F waviness meter

Germany KB Vivtorinox hardness tester

Finland residual stress analysis

Oxygen nitrogen analyzer from USA

Germany Zeiss metallographic microscope

Steel ball single body vibration measuring instrument

NG Spectrometer spectrometer

Bearing life testing machine

Hydraulic universal testin machine

We produce

| Item | Name | Material |

| 1 | Carbon steel ball (Low) | AISI1010,AISI1015,Q195,Q235 |

| 2 | Carbon steel ball (High) | C80,C82,C85 |

| 3 | Stainless steel ball(Austenitic) | AISI304/304L/316/316L/201/665 |

| 4 | Stainless steel ball(Martensitic) | AISI420/420C/440/440C |

| 5 | Chrome steel ball(Ferritic) | AISIE52100/100Cr6/Gcr15/SUJ-2 |

Packaging

1. Plastic bag+box+carton+wooden pallet

2. Plastic bag+carton+wooden pallet

3. Export cartons+steel drums+wooden pallets